3 Fascinating Facts about Engineering Design Services in Mumbai without going into details

Mumbai is a burgeoning service market. It has so much potential that it can deliver to any product or service industry.

Speaking specifically about Engineering Design Services in Mumbai, the presence of any competitive small scale industry is vast, and analyzing what patterns they follow, what industry is looking for, and combining them with reality and presumptions is the key here. This necessitates the use of expert engineering design services.

The significance of engineering designs varies depending on the type of products you commission your engineer to create. In almost all cases of industrial design, you will determine the need, and then your engineer will determine the design and how much of it must be engineered.

Some features, for example, that are to be manufactured in plastic require different details than those that are to be manufactured in aluminum or steel. One product may be designed simply in one material, but another may necessitate more extensive analysis and engineering.

Industrial design is sometimes less about appearance or style and more about working with a specialist in materials, optics, mechanics or manufacturing to solve problems or complications that affect cost or tint. Industrial design is, in part, a combination of craft and technical skills, knowledge, and practice that a layperson cannot perform. It requires a professional touch to become what you expect.

Why you need to hire Professional Services:

Engineering design is a great field for creativity, innovation, and research. It is primarily concerned with dealing with practical issues that must be resolved and planned for in the future. As a result, it is necessary to invest in skilled engineering design services that approach each problem in a unique and systematic manner.

Thus, the primary goal of engineering design is to apply scientific knowledge to technical problem-solving. While engineers provide a technical solution, it is critical to understand that engineering design implies an aesthetic solution as well.

In other words, designers are also involved in ensuring that the end product is cost-effective, environmentally friendly, and appealing to users.

Among the engineering designs are some of the following:

- Mechanical CAD Design

- Electrical CAD Design

- Civil and Structural Design

What are the steps involved in the Engineering Designing Process?

The Engineering Design Process is a set of steps that engineers use to create processes and products.

Many variables and parameters must be chosen during the engineering design process, which demands a professional touch. Let us take a closer look at how engineers and designers work on each detail.

The following are the steps in the design process:

Conceptualizing the design is the first phase of the project.

1. Awareness of a requirement

The first step is to identify a business and product development opportunity.

This is discovered through market research, as well as customer interviews, surveys, complaints, and warranty data.

2. Problem clarification

Problem definition in the engineering design process takes the form of identifying customer needs that a product will meet.

As a result, in this step, the customer’s requirements are translated into design parameters.

Engineering characteristics such as parameters, design variables, and constraints that communicate how the customer’s needs will be met are used by design teams to describe the end product.

3. Information gathering

The design information of existing or similar products is gathered in the following step, which necessitates knowledge of a diverse range of information sources. These sources include the Internet (World Wide Web), business catalogs and other trade literature, technical reports and patents, and published technical literature, such as technical magazines produced by Corporate consultants.

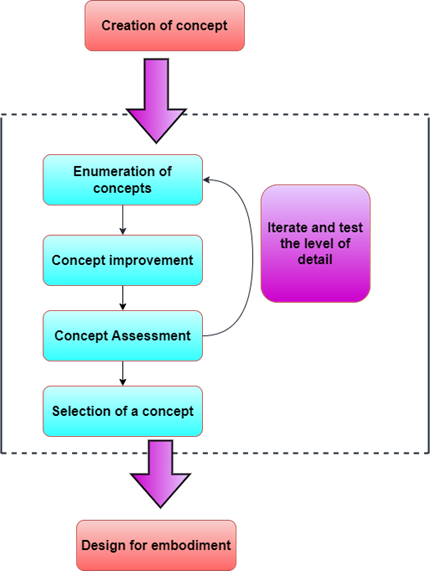

4. Creating a design concept

After gathering all relevant data, the designers begin the real work by drawing simple and multiple sketches of the product based on the customer’s requirements.

5. Evaluation and selection of concepts

Before deciding on a concept, the designers are involved in multiple concepts from previous steps that are then evaluated in terms of important design parameters such as safety, durability, strength, and so on.

Designing Embodiments in Phase II

6. Determining the architecture of the product

Following the completion of the product concept, the engineering designers prepare concepts for individual parts/components in the same manner as in steps 4 and 5.

7. Design of configuration

This step is a little more difficult because it includes material selection, modelling, and part sizing based on design and safety constraints.

The measurements provided are only estimates.

DFM (Design for Manufacturing) / DFA (Design for Assembly) principles are also used by designers to reduce costs and increase efficiency.

In addition, the final evaluation of the critical parts is prepared using a variety of methods, including Pugh’s method, among others.

8. Parametric layout

Following that, the manufacturing process for each component is defined here. The final dimensions and tolerances are determined by the function.

Detail design in Phase III

9. Design of fine detail

During this stage, the designers finalize all major details such as the manufacturing process, material selection, and part dimensions.

They also publish the final part drawings and specifications for manufacturing.

Even after the drawings are released, there may be some minor issues due to a variety of factors, or various Departments may recommend improvements. Thus, professional designers conduct reviews on a regular basis to assess and analyze problems and further improvements can be implemented if required and demanded by the engineering designers.

Let’s wrap up:

Engineering a product is a difficult task; engineering design is similar to a dress rehearsal for the engineering job. Being creative while also being sensitively responsible is essential for designers, as they must thoroughly demonstrate their mastery of the engineering craft. Before hiring a service, you should check to see if they are cost effective and work within your budget.

Last chance to hire a Hitech Innovative Engineering Design Services in Mumbai:

Wakidok Innovative Solutions is a group of highly dedicated, young, and energetic engineering design service providers based in Mumbai. To deliver the solutions, we are obligated to employ a systemic and creative problem-solving approach.

We also have more than a decade of industry experience and use ROI-focused tools. Our dedication undoubtedly adds value to the lives of our clients.

We recognize your worth and are committed to meeting your requirements!!

Click here for a no-obligation consultation with one of our expert designers!!